UH 60 Parts Magazine: Comprehensive Listing of Components

Wiki Article

The Importance of Correctly Sourcing UH-60 Components for Safe and Efficient Procedures

The significance of appropriately sourcing UH-60 components can not be overemphasized, as the stability and safety of air travel procedures rest on the quality of these elements. Using certified parts not just guarantees conformity with strenuous design requirements however likewise alleviates the risks connected with subpar alternatives. The implications of sourcing decisions expand past immediate operational effectiveness, affecting long-term maintenance costs and aircraft integrity. As we explore the critical aspects of sourcing carefully, the critical advantages and covert difficulties may reveal understandings that are essential for maintaining operational quality.Recognizing UH-60 Component Specs

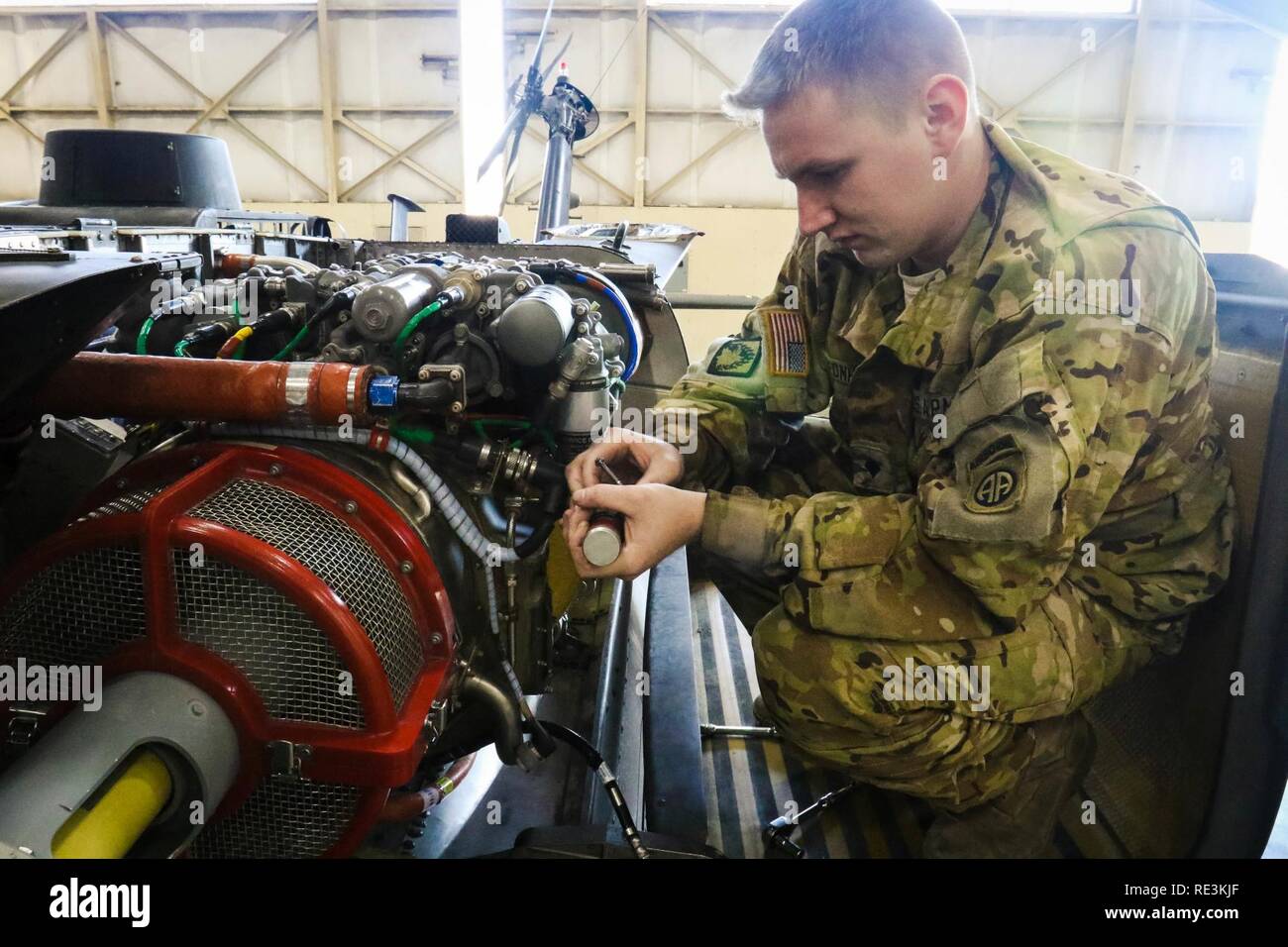

Recognizing the complexities of UH-60 component specifications is important for ensuring operational effectiveness and safety and security in aviation upkeep. The UH-60, widely used in civilian and armed forces applications, needs components that fulfill strict design and governing standards. Each part is meticulously made to carry out under particular conditions, and discrepancies in specifications can result in efficiency failings or safety and security risks.

Part specifications include different qualities, including product composition, dimensional resistances, and functional limits. For example, rotor blades need to adhere to specific weight and aerodynamic profiles to ensure optimal trip attributes. Additionally, parts have to undertake rigorous testing to validate their dependability and durability within the requiring settings regular of aeronautics procedures.

In addition, recognizing the qualification procedures related to UH-60 parts is important. Each component might bear markings suggesting compliance with military or market criteria, making sure that it has actually undergone the necessary inspections and top quality assessments. This conformity not just safeguards the aircraft's performance but likewise cultivates accountability amongst suppliers and producers. Consequently, complete understanding of part specs is important for maintenance personnel, allowing them to determine authentic parts and preserve the functional integrity of the UH-60 fleet.

Dangers of Utilizing Substandard Parts

The stability of aviation operations rests on the high quality of parts used in airplane maintenance, particularly for the UH-60. Utilizing ineffective components postures significant dangers that can jeopardize both safety and operational performance. These parts may not fulfill the rigorous requirements developed for military air travel, causing unpredictable efficiency and potential system failures.Substandard components can cause boosted deterioration on important systems, eventually shortening the life-span of the airplane and requiring pricey fixings or substitutes. Additionally, the use of substandard products might cause devastating failures throughout flight, endangering the lives of crew participants and travelers alike.

In addition, dependence on non-compliant components can expose operators to regulatory and lawful consequences, as aircraft must follow rigorous standards stated by controling bodies. This could result in grounding of the airplane and considerable operational delays.

Benefits of Licensed Elements

Licensed elements provide a wide variety of advantages that substantially improve the safety and dependability of UH-60 procedures - uh 60 parts. One of the main advantages of these elements is their adherence to stringent top quality criteria. Accreditation procedures make sure informative post that each part has actually undertaken strenuous screening and assessment, thereby verifying its efficiency and resilience under different functional problems

The assimilation of qualified elements likewise assists in smoother maintenance treatments. Technicians can be confident in the integrity of these components, lowering the probability of unplanned repair work and enhancing overall functional performance. The long-lasting cost-effectiveness of certified components can not be overstated; while they may come at a higher preliminary cost, their integrity and efficiency translate right into reduced maintenance and substitute costs over time. Ultimately, spending in qualified parts is crucial for the risk-free and efficient operation of UH-60 aircraft.

Sourcing From Trustworthy Distributors

When sourcing components for UH-60 aircraft, partnering with credible providers is critical to guaranteeing high quality and reliability. The security and performance of armed forces airplane depend significantly on the stability of their components, making it imperative to choose providers with a tried and tested performance history in the market. Trusted vendors follow strict quality control measures and commonly hold relevant certifications, which function as a testament to their commitment to excellence.Along with quality control, established suppliers offer thorough support services, including technical help, guarantee programs, and timely distribution. This level of involvement is crucial for maintaining operational preparedness and decreasing downtime. Trustworthy providers are generally extra clear concerning their sourcing techniques, guaranteeing that the components offered satisfy rigorous regulative standards and are compatible with existing systems.

It is likewise helpful to think about providers who specialize in UH-60 parts, as they have comprehensive expertise of the airplane's specifications and requirements. By leveraging the experience of these distributors, drivers can improve the security and efficiency of their operations, inevitably bring about boosted objective success. Investing time in sourcing from reputable vendors is a crucial step towards attaining ideal performance in UH-60 airplane operations - uh 60 parts.

Long-Term Cost Effectiveness

Accomplishing long-term expense efficiency in sourcing UH-60 components requires a strategic method that stabilizes initial financial investment with recurring functional expenses. Organizations must prioritize top quality over cost, as substandard components might result in constant repair services and raised downtime, inevitably inflating total costs. By buying trustworthy, licensed visit the website parts, operators can enhance the airplane's performance and long life, mitigating the threat of unanticipated failures.Furthermore, developing lasting relationships with respectable vendors can generate monetary advantages, such Extra resources as bulk purchasing discount rates and favorable payment terms. These partnerships promote access to remarkable products and technical assistance, making sure that the sourcing process aligns with regulative requirements and operational demands.

Additionally, applying a methodical stock administration technique permits far better forecasting of component needs, reducing excess stock and linked holding costs. Consistently evaluating provider efficiency and component integrity can likewise notify future investing in decisions, making it possible for companies to adapt to advancing functional needs successfully.

Inevitably, a concentrate on lasting expense performance in sourcing UH-60 components not only safeguards operational honesty however likewise adds to an extra lasting economic version, enabling reinvestment in essential aviation abilities.

Final Thought

In final thought, the appropriate sourcing of UH-60 components is crucial for preserving efficient and safe aviation operations. Sticking to rigid specifications and utilizing certified components alleviates the threats linked with subpar components.The significance of correctly sourcing UH-60 components can not be overstated, as the honesty and security of aeronautics operations hinge on the quality of these components.Recognizing the ins and outs of UH-60 component requirements is crucial for guaranteeing functional effectiveness and safety and security in aeronautics maintenance. Detailed expertise of component specs is crucial for upkeep employees, enabling them to determine genuine components and preserve the functional honesty of the UH-60 fleet.

When sourcing parts for UH-60 aircraft, partnering with respectable distributors is crucial to making certain top quality and reliability.Accomplishing long-lasting price effectiveness in sourcing UH-60 components calls for a critical method that balances first financial investment with recurring functional expenditures.

Report this wiki page